Are There Sustainable Tile Options?

December 7, 2023

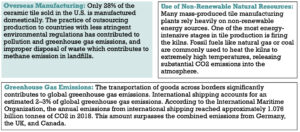

Modern tile manufacturing can be unsustainable, but tile has been made for centuries and it wasn’t always resource intensive. Certain companies are trying harder to use different techniques in their tile manufacturing that have a lower environmental footprint. From raw material extraction to kiln firing to shipping, tile manufacturing can be unsustainable.

So how are U.S. manufacturers addressing these common issues in tile production?

Domestic production can lead to a simpler and more transparent supply chain, allowing for better oversight and control over the entire manufacturing process, potentially reducing inefficiencies and environmental impacts.

Fireclay Tile

Fireclay Tile is the first tile company to be a certified B Corporation, meaning they demonstrate a high social and environmental performance. The majority of their tile is made to order, with a small selection of ready to ship items.

Recycled Content: 80% of Fireclay’s tiles are made from recycled materials, including post-consumer recycled glass and pre-consumer recycled granite dust. This includes materials like recycled porcelain and other waste materials diverted from landfills.

Energy Efficiency: Fireclay Tile emphasizes energy-efficient manufacturing practices, striving to minimize energy consumption and reduce greenhouse gas emissions. Their factory uses 100% renewable electricity and they offset carbon emissions from all parts of the manufacturing process including sourcing raw materials, the entire production process, and all inbound & outbound freight emissions.

Closed-Loop System: Fireclay Tile operates a closed-loop system, recycling and repurposing excess materials generated during production. This approach minimizes waste and promotes a circular economy.

Artisanal Craftsmanship: Fireclay Tile stands out by employing skilled artisans who handcraft tiles, ensuring attention to detail and quality control. This approach supports local craftsmanship and creates unique, custom tiles with reduced environmental impact compared to mass-produced alternatives.

Customer Education: The company actively educates customers and design professionals about the importance of sustainability in the tile industry and the benefits of choosing eco-friendly products.

Bryce Canyon, Bora Bora, and Limon

Photo by Logan Havens

Red Rock Tileworks

Red Rock Tileworks out of Nashville, Tennessee is another U.S. based clay tile manufacturer implementing sustainable practices. They are a small business in the tile world, but making waves and rapidly growing. They are constantly finding new ways to reduce, reuse, and recycle throughout their manufacturing process. Their efforts in reducing their environmental footprint is so effective, they do not use a commercial sized dumpster, all their waste can fit in a residential sized bin.

Salvage: 95%of their equipment is either used or fashioned from old materials, giving them a new purpose and diverting waste from landfills.

Recycling: Redrock recycles all of their clay. If a tile doesn’t come out of the mold right, they grind it back into dust, add water and it is used to make new tiles. Scrap clay, contaminated from the bottoms of shoes, is collected for a local gardening company that uses it for landscaping. In addition, water is reclaimed and purified on site and reused. The reclaimed water is used to clean their glaze booths and tools at the end of the day.

Energy Efficiency: In the winter the kilns provide the tileworks with heat and in the summer the open air truck docks and fans provide the cool.

Artisanal Craftsmanship: Red Rock is a collection of skilled artists that create enduring products that reflect artistry and craftsmanship, and ensures attention to detail and quality control.

Shipping: All field tile is wrapped in post consumer recycled paper and their packing peanuts are biodegradable. In addition, their central location provides them with less shipping costs and fuel usage than coastal manufacturers.

Photos by Logan Havens

Domestic tile manufacturers are increasingly recognizing the importance of sustainability and are actively implementing measures to combat climate change. By embracing renewable energy, reducing emissions, incorporating recycled content, and adopting eco-friendly practices throughout their operations, these manufacturers are contributing to a more sustainable and environmentally responsible tile manufacturing industry. Choosing tile made in the US is one way you can make a difference.